|

**

WARNING **

Old Abandoned Underground Coal Mines can be

Very Dangerous,

Due to Collapse, and Mine Gases (Noxious and Flammable).

Extreme Care should be taken around them, due to Falls, Sudden Ground Collapse,

and Bad Air,

and in NO Circumstances should People enter into ANY Mine Openings, or

Associated Caves.

The Material Contained on my Sites, is NOT to Encourage Personal Investigation

of these Mines,

But only as a Historical Record of these Long Abandoned Mines.

Please View these Mines from a Far, Safe and Legal Distance.

Always Observe Private Property Rights, and Obey ALL Warning Signs.

************************************************

|

Below is my compilation of various history books, census forms, Canadian

and British, Birth & Death Records, UK and Saskatchewan, Cemetery

Records of Rosemary Mack, Canadian Archives material, and various family

histories, from many books, plus my Mom's old scrapbooks, with Estevan

Mercury articles, pictures, Leader Post articles and pictures.

I do not take credit for any of this material, other than the compiling

of it here. Being old history, most over 100 years, I doubt

if it is copyright any more, but if any of the info below is copyright,

and you want to see it removed, please feel free to contact me.

But I hope for the sake of preserving history, this will not happen.

I am not selling this info, I am not profiting in any way on publishing

it here. I am only trying to show all this information in one

place, it took me many hours to accumulate the story for printing here.

I hope you all enjoy it. It is as accurate as I can get it at the

moment. I am sure like everything else I do, there is errors.

I am not perfect. If there is an error, please let me know,

and I will recheck my info, and we will sort it all out. I've seen

lots of so called well researched books, and have found many errors in

them, so I may or may not be wrong. I've noticed the family

histories are the most prone for errors. Usually written by a

granddaughter or grandson, the dates and info passed on, can be fuzzy at

best. I do appreciate their effort to document their family, as an

amateur genealogist, I know what it's like. We all try our best.

If I was paid for this, I would travel the world, to gather the

documents, but for free, this is what you get.

I have found some new newspaper clippings,

which have revised the order and dates quite a bit, on the mines and

work in this area. I have added new pages, with links from this

page or the town index pages.

Coal

Mine History in SE Saskatchewan

First to see the

coal in this area, would have been the Natives in the area.

I don't know if there is any written record of them using the coal though.

Assiniboine, Chipewans, Sioux,

and Cree, all were here,

as early as the 1700's.

Geological terms, this area is part of the Paleocene Ravenscrag formation.

Prior to coal being reported in the area, the

First White Men had a few expeditions into this area.

Two Sons of Pierre Gaultier de Varennes, sieur de La Vérendrye(1685-1749)

or Pierre La Verendrye (Sr.) for short, in 1742, were at least close to this area,

on their way west in search of a western sea, or river that flowed west..

They named the Souris River, the St. Pierre river, after their father.

Earlier in 1731, La Vérendrye left Montreal

with three of his four sons,

Jean-Baptiste, Pierre, and François, and

made it as far as Winnipeg,

before turning south to the Missouri river.

In 1742

Pierre La Verendrye (Jr.)

and one of his other brothers,

came exploring and possibly came into this area.

Again nothing documented that I know of.

Rock engravings at Roche Percee show early dates of

1773, to 1810.

Possibly Hudson Bay Company

fur traders who came through the area.

Again not much recorded, in the way of coal deposits.

The Lewis and Clark expedition, in

1804 was exploring

along the Missouri and its tributaries when some of their party

went north to see the Roche Percee rock formations.

No record of finding coal was reported in their records.

No doubt the sand outcropping drew them there.

All of these early explorers used Native Indians as guides,

as well as talking with them, they learned of various things,

that were important to them, such as Roche Percee.

The Lewis

and Clark trail passes Roche Percée Natural Arch, seen by Lewis and Clark on

June 6, 1804.

The Native Indian legend below, written about here in 1906, says

a century earlier this story happened, so it seems ca

1806, the coal was seen by this

lone fur trapper. Are those his initials scratched on the walls of the

stone described above? Too bad there is no name here. Wonder what happened to the

carving?

In 1849

Captain John Palliser was near this area,

but not known if he actually made it to see the coal deposits.

It is speculated he did, and the reason he returned in 1857.

The first

"official" written record of the coal deposits came in 1853.

Four United States Railroad surveyors were mapping a route to the Pacific

for a railroad from the Mississippi river, and discovered lignite coal in 1853

along the Souris Valley.

There was nothing done then about the discovery, and their writings.

In 1857 the Palliser Expedition

was sent out by the Canadian Government

to explore that portion of British North America.

They had heard of the Sandstone structure at Roche Percee,

and went 60-70 miles southward from Fort Ellice to see it for themselves.

They reached the Souris Valley on August 21, 1857,

a short distance east of Roche Percee.

a Doctor James Hector (Naturalist)

and Captain John Palliser

were involved.

On the sides of

the valley, a thin seam of lignite coal was exposed.

It was written about, but nothing was ever done.

The

Boundary Commission went through this area

just before the NWMP.

Excerpt from Harper's New Monthly Magazine, Volume 0022, Issue

129 (published February 1861)

Chapter Title: Red

River And Beyond, Page 309,

Author: Marble, Manton states this:

"We had been repeatedly informed by half-breeds (Metis) of the

existence of coal or lignite in strata in the banks of Mouse

(Souris) River, and Saskatchewan. Governor McTavish showed

us pieces of lignite from that river- the first that we had

seen- and confirmed the fact of its existence on the upper

waters of the Mouse (Souris) River. He added that it was used

habitually during the winter at Fort Pitt, and a retired chief

factor, whom we afterward visited, told us that at his former

station, at the Carlton House, it had supplied their

blacksmith's forge."

Chief Factor of Fort Garry, and Governor of the Colony of

Assiniboia, appointed in 1858, was William McTavish, Scotch

birth or descent, per this book. He came to the Bay in

1833, becoming Chief factor at York Factory at one point. He

moved to Red River from York factory in 1857.

b-1815 in Edinburgh Scotland, died July 1870, in Liverpool

England of TB.

Manton Marble (1834-1917) was a New York journalist. He was the

proprietor and editor of the New York World from 1860 to 1876.

In 1859, he went

to the Red River Valley as The Evening Post's correspondent,

contributed 3 articles to Harper's magazine, one of which is

above.

On July 24, 1874, the North-West Mounted Police,

on their march west,

camped at Short Creek, and burned Lignite coal in their campfires, and

forges. Still nothing was done about these discoveries and records. Lots written

about the coal, but still no real mines.

Major James Morrow Walsh was in

charge of D troop, and he later returned to the area, setting up the

Dominion Coal Company,

the first Big Company Coal Mine at Estevan.

Dr. George Mercer Dawson in a

1875 published report

commented on the rocks at Roche Percee. He said "they owe their curious

forms to the weathering away of soft sand from the bed of hard rocks, which is

rendered durable by an abundant calcareous cement."

Dr. G. M. Dawson was born Aug 1, 1849, in Pictou, NS. In 1873 he was

appointed geologist and botanist to her Majesty's North American Boundary

Commission. He mapped the Tertiary Lignite Coal which was originally noted by

James Hector during the Palliser Survey of the 1850s. Dr. Dawson died Mar. 2, 1901, after becoming sick in his Ottawa office 2

days earlier. He was the son of Sir John William Dawson. He attended the

Royal School of mines in London for his training.

Sept 28, 1876

Here we see in writing that the coal

in the area was well known.

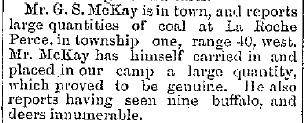

Nov 27, 1879

Mr. G. S. McKay reports on the coal at Roche Percee

Township 1, range 40?, west

He was a bit off on the range?

Seems like a few buffalo still around at that time.

Haven't been able to pin down this fellow's history

Mr. Hugh McKay Sutherland,

President of the Winnipeg and Hudson Bay Railway and Steamship Company,

from Winnipeg,

came west, with several men

to see what all the excitement was about for himself.

He actually started to ship coal to Winnipeg in the

Spring of 1880, barging the coal

to Winnipeg.

Jan 27,

1880

The Murdock Party left Winnipeg

to explore the route for the proposed

Government Railway to the Souris Coalfields

Actually left with Dog Trains on this day.

Haven't been able to find more info on this Murdock

May 27,

1880

Thursday Morning, June 10, 1880,

Victoria Daily Colonist printed the story:

Prof. Selwyn of the Geological Survey,

has arrived at Winnipeg en route to study

the geological formation of the Souris Coal Field

Aug 28, 1880

Now we see some serious drilling being done.

Mr. William Henry McGarvey

was hired by the Dominion Government,

and did testing 10 miles east of Roche Percee.

They drilled to 362 feet,

and struck a seam of coal 6 1/2 feet thick.

which they claimed was better quality

than at Sutherland's mine, upstream

at the sandstone outcropping.

see my

Coal

Mines in the Area page

for Mr. McGarvey's bio

Shortly after this he became

probably the world's richest man.

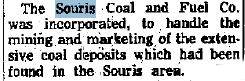

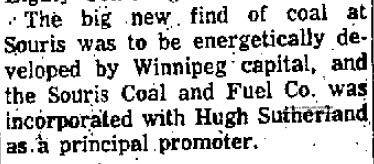

Sept 22, 1880

Hugh Sutherland's Company

The Souris Coal and Fuel Company

was the big player in the game.

Dec 10, 1880

1881, First Coal

brought to Winnipeg

by Hugh Sutherland

Mar 13, 1882

Government Report Minister of the Interior

on Roche Percee Souris Coal discussed

Report is actually for year ending June 20, 1881

The June 1882 discovery, is the

story of the two Pocock brothers,

who came to the Souris (Mouse, St. Pierre) River to shoot non-existent buffalo.

Coming from England, they were told buffalo were everywhere on the plains.

During their "hunt", they encountered some of the main coal seams.

The big problem,

even though they all knew the coal was here, was the way to get it out.

Wagons were used locally, but not good enough for major mines. River was

not high enough at all times, so water transport was ruled out by Mr. Hugh

Sutherland's attempt. that left the railroad, and until the Manitoba

South-Western Railroad extended to here, nothing was to happen, other than local

farmer sales. When this railroad was sold to the CPR, the extension was

made, and the rest is history. Now they had a relatively cheap way to

transport the coal to Winnipeg, and points east. Strange as it sounds, but

most of this early coal for years went east, virtually none was used in

Saskatchewan. Regina being closer, did not get a lump of this coal.

Seems strange to me, how about you. these mines were controlled from

Brandon and Winnipeg, and that is where the coal went.

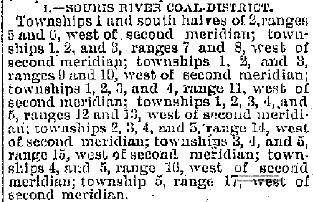

Oct 22, 1883

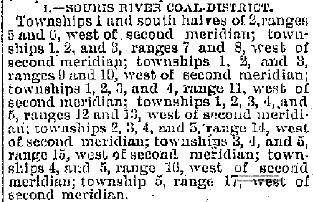

Souris River Coal District is outlined.

May 19, 1889

It was reported that the Canadian

Pacific Railway Company

has agreed with the Canadian Government

to build a branch line from Brandon southwest

100 miles to the Souris coal district,

and also an extension of twenty-five miles

from the present terminus of the

Manitoba and Southwestern Railway

to a junction with the projected Souris branch.

The company gets the usual grant of 6,400 acres to the mile.

Sept 29,

1891

Major Walsh announced the Souris Coal Mines

will be producing Coal shortly

The first Real Productive "Commercial" Coal Mine in this area was

east of Roche Percee in 1891. Shafts as deep as 90 feet down

were dug in that area. The

Hassard Mine was its name,

was owned by Hugh Hassard. I created the separate web page for this mine, as it is so important to

the history of the area.

His mine was later to become the Souris Valley

Coal Co. mine

in 1895, with a 8ft coal seam. Located on

SE 1/4 of Sec 4. tp2, Range

6, W2nd, east of Roche Percee.

An article I have states there was 2 mines, the Hassard

mine, down below the old stone house, and

Daddy Gow's mine, 1 and 1/2 miles east

of that. The author says both of these mines were working in 1890-1891.

Alex Dunbar was a miner in the Gow mine. This article also states the

first crossing was a bridge 1/4 mile east of the present Taylorton bridge.

it was built they claim in 1892. This would have been the bridge that

washed away in 1904, from another book. It was built while the Soo line

trestle just south of there was being built.

The Price Mine is also

mentioned next to the Hassard mine. The Bio for Mr. Hiiliard Edwin Price is on

my

Coal

Mines in the Area page

Souris Valley Coal Mine was sold to the Taylor

family of Winnipeg

and renamed Western Dominion

Collieries ltd. This is the name that Taylorton

comes from.

One source on the Pocock story,

says it was Jim and Tom Taylorton

that started a mine in 1887. This I have not found anywhere else.

Another

version said The John Taylor Family who came from Winnipeg Manitoba, but

John was only one of seven sons of Richard, and he was appointed to

manage the mine only. Another of Richard's sons was

R.R. Taylor Jr. All of this info comes from a family source,

Kaye Taylor, wife of Delbert G. Taylor, who is the Great-Grandson of

Richard Radcliffe Taylor. Also adding info was Rhonda, Kaye

and Delbert's daughter. I thank them all very much for this update

on history.

Now we know it was named after

Richard Ratcliffe Taylor Sr.

1904 Government

Report by

Donaldson Bogart (Donald) Dowling, B, Ap. Sc.

(b- Nov 5,1858 in Ontario - May 26, 1925)

Deep Seam Coal Mining

A mine could not open without the

proper permits. Mine Inspectors from the government were constantly

looking for mines operating without the proper paper work. They also did

safety inspections of the working mines.

First an owner or operator had to

obtain mineral rights for the land. Owning the surface land was not

enough. They had to have a pit boss that would constantly survey the area,

to ensure they were mining on their own property. He was also responsible

for the safety of the mine, width of the pillars left, and properly timbered as

they went deeper.

The best grade of Lignite coal

in this area was about 100 feet below the surface. They dug an entry from

a hillside, on the bank of the Souris River, at a slope, or an angle, down to

reach this seam. Thickness of the seam was up to 14 feet (4.27 mtrs), but

averaging 6-7 ft.. the entry was 8 ft (2.4 mtrs) wide, down to the vein,

then 2 entries were driven into the vein, with 24 ft (8 yds) (7.3 mtrs) wide

rooms at right angles on either side of these. Pillars of coal, 6 ft (1.8

mtrs) wide were left between these rooms to support the roof, and then cross

cuts were made for air circulation. This form of mining was called

the Conventional Room-and-Pillar Method,

also known as Bord and Pillar method in England, was

used in many parts of the world, prior to this area. It is one of

the oldest forms of underground mining known. It creates a grid like

pattern underground. They did not do retreat mining, as was used in some mines

later on. Bord (also spelled board) is another term for a coal roadway, or

side gallery, or room,

It was

probably a system invented in England.

As they dug deeper, air shafts were

dug to the surface to supply air to the mine deep underground. They used a

fan at the bottom of the slope to circulate the air. They used

these fans at noon and evening after they used black powder shot to extract the

coal, to evacuate the thick smoke it generated. Some mines used children

to open and close big doors in a rapid manner, to create air movement.

They used electric cutting and shearing machines later on, which made it a

little safer.

All work was done by the light of the carbide lamp, worn on a cloth hat by the

underground miner. No breathing apparatus, no air quality testing

stations. No real safety equipment of any kind.

Light rails were laid, and coal was loaded into

mini coal cars, then towed by horses to the bottom of the slope. My dad's

job underground was looking after horses that did this job. The larger

mines used vertical shafts to raise the coal to the surface on a hoist.

They only used the slope for the men to enter and exit the mine. They also

used electric trolleys, rather than horses to tow the cars, which were also

larger than the first mines in the area.

There you have it in a nut shell, the abbreviated version of how the Coal Mines

were developed in SE Saskatchewan, and a very basic description of their

operation method. |

Types of Coal

ANTHRACITE

Highest Carbon Content- 86-98%

15,000 BTU's/LB

BITUMINOUS

45-86% Carbon Content

10,500 - 15,500 BTU's/LB

SUB-BITUMINOUS-

35-45% Carbon Content

8,300 - 13,000 BTU's/LB

LIGNITE

(Also known as Brown Coal)

This is the type of Coal in SE

SASK.

25-35% Carbon Content

4,000 - 8,300 BTU's/LB

The bad side is Lignite is the lowest grade,

the good side, there seems to be lots of it here.

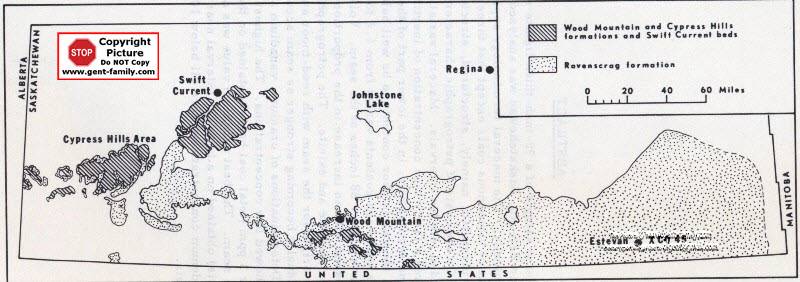

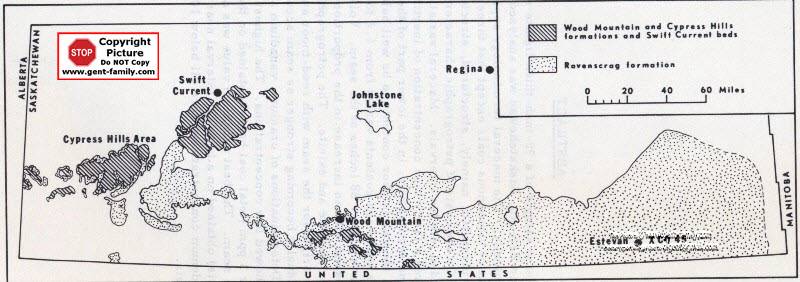

Saskatchewan Coalfields Map

Bienfait/Estevan are part of the Ravenscrag formation

the dotted area in map above

map courtesy Mr. Grant Walker, CA, USA

First Shovel in the area of our Farm house

located 1 mile south of Bienfait.

Picture dated Jan 27, 1953

My

Dad's Story, as remembered by myself

My dad started working in the coal mines in 1931.

He was working in the coal industry

until 1977 when he retired, age 65.

His first job was hauling coal with horse and wagon,

and hand shovelling it into a Box Car at the siding in Roche Percee.

He started at the Eastern Collieries later in 1931.

He supplied a horse, and hauled coal with a dump cart for .28 cents/hour

In 1933 he started working underground,

driving and working on coal cutting and shearing machines.

In April when the tipple burnt down,

He was one of three men that filled the shaft with two wheelbarrows.

Later he worked at the Wilson #2 mine.

After that he returned to the eastern mine

to work on rebuilding the new Tipple.

In 1958 he started to work at Utility Coals,

until he retired in 1977.

He was in charge of the horses

underground ,

that were used to haul the coal-cars

from where the cutting machine

was,

to where the coal was hauled

up to the tipple.

He told many stories of these

days,

and it is too bad VCR's and Camcorders

were not around in the 70's

to record these for future generations.

Some of the stories I remember

are the fact that the horses

were taken underground

and never brought up until they

died.

If they were to be brought to

the surface they would go blind, from the sunlight.

My Dad loved these horses as

much as he loved us, I am sure.

He used to tell us how

the brakes would fail on the ore car

and literally run down, and over

the horse,

and all the bosses would say

is

"get another horse and get working"

.

No down time for a crippled or

dead horse!

Same would happen when a man

died underground,

it was work as usual shortly afterwards.

Dad used to tell us the dead

or injured man

would be brought to the surface

on a grain door.

No fancy stretchers or first-aid

men here.

My Dad told us he had many close

calls,

and danger lurked around every

corner.

The only difference was if the horse died,

there was lots of explaining to do to the boss,

as they cost money to buy.

There was 100 men around the corner to replace a dead one.

Years later on hearing of an

underground explosion

and men trapped my Dad would get

a tear in his eye

and I am sure a little prayer

was said.

The Coal miners stick together

even after coal mining!

Stories have been told,

and songs have been sung about

the company store,

but looking at the pay stub below,

you can see they were all true.

A miner had to buy his own carbide

to light his lamp underground.

Tool rental was charged to dig

the Coal for the company.

Prices were outrageous and if

you didn't buy at their store your

job was in jeopardy, and also your company housing.

He would tell us the story behind

the miners strike that ended up

with the RCMP killing 3 miners

on Sept 29, 1931.

These miners are buried in the Bienfait cemetery,

and every so often a yellow stripe

is painted

on the tombstones to show the

RCMP involvement.

This same stripe gets scrubbed

off every so often

by police sympathizers.

The Library in Bienfait has a

very good video,

that all interested in this era

should view.

I believe it was produced

by the CLC.

It has both perspectives in it.

Interviews with the Police Chief

in Estevan at the time,

and also interviews with miners

from that era.

It shows the living and working

conditions of the miners.

The cheating on the pay. Most

miners were paid by the hour,

but some I guess were paid by

the Coal-car load,

(they had to load the car by

hand)

and were paid by the weight of

the Lignite coal they loaded.

The person weighing the

coal was management,

(or in bed with them),

and would say the weight was

less than it actually was.

Another way for the company

to shaft the men.

A definite must see!

Wonder why there is Unions today?

Today you can see depressions

in the ground

between Estevan and Bienfait

and most of these

would be underground cave-ins

from these old mines.

Just before my Dad died, he was

called upon

to identify old mine locations

to the authorities,

so these could be looked at.

Cave-ins could be very dangerous,

and over the years people have

climbed into old mines etc.

and have been buried alive.

Recently I believe some children

were involved.

Today there is not many alive

who know where these mines were,

so they can be checked and dismantled,

to eliminate the danger.

The mines took their toll on my

Dad's life, and over the years he

had an operation on his diaphragm,

and also had other

breathing difficulties. It definitely

shortened his life.

I feel sorry for those that endured

the same fate.

Years ago, in Estevan, they started

to recognize

the "old" miners of the area, and

a "Lignite Louie"

was chosen each year. I hope

this has continued today.

Oil became the resource in the

50's & 60's,

and Coal mining was their poor

cousin.

Thank God for people like Mr

Leonard Gadd, Mr Souther,

and now the Walliser family, who worked at,

and helped maintain the Little

Museum in Bienfait,

devoted almost totally to this

way of life.

I am sure people who live

in Estevan haven't been there.

What a shame. Schools should

be taking trips down there

to see this display.

Without the Coal the people might

not have even settled there.

The farmer those days barely

made a living

and without the coal mine would

have barely existed.

Would the train have come to

this area? I doubt it.

Would the Power Plant that feeds

electricity to that area exist?, No.

I could go on and on.

We owe a huge debt to Coal and

the Miners who worked with it.

As an aside to the Power plant

and acid rain issue,

I remember as a kid seeing nothing

but white alkali soil everywhere,

nothing would grow near any slough,

but today all sloughs are green

and lush and loaded with ducks.

Some areas need a little acid to balance

the PH,

and I think this is one. I am no Geologist

etc. but it

does not look like it is hurting

this area too much anyway.

There is so many environment issues today

that emissions are much reduced from the past.

The reclamation of the land is

much improved

also so if it has to be mined,

they seem to be doing it right.

We need jobs, we need power,

so not much you can do.

A hell of a lot better

than nuclear in my eyes!

My dad saved some of his mining

equipment

and today I have those in my

possession,

and these will be handed down

to my son to be passed

down to his offspring maybe some

day.

I love to show this material

to people

and am very proud of my dad and

his involvement.

I have his carbide lamps, plus

Dad's first " hard hat" that wouldn't

save too much of anything, but

keep coal dust off your hair!

It is made out of a type of press

wood

that you see in cheap bowls today.

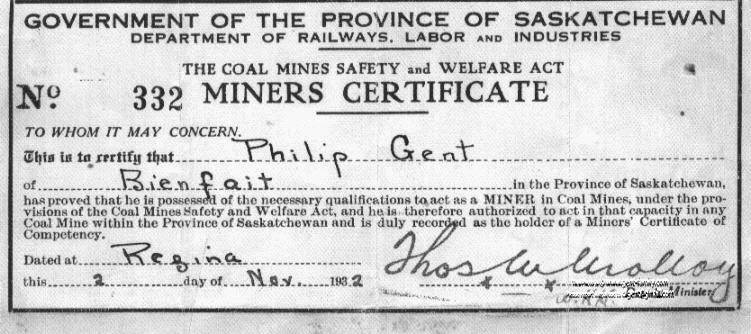

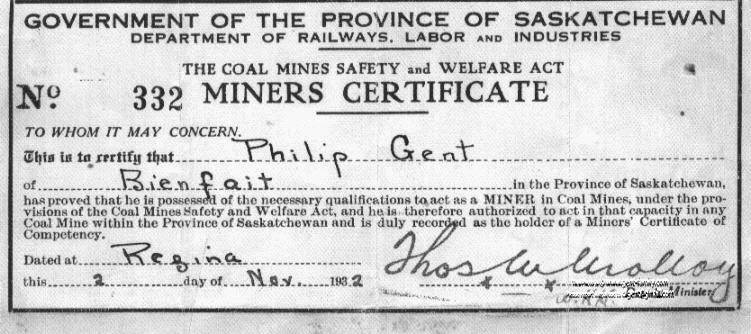

This is a copy of my

Dad's "Miners Certificate"

from 1932

Below is the Feb 20th, 1980 article from the Estevan

Mercury

showing my dad and others being honoured,

by naming them Honorary Lignite Louie's on Feb 13th, 1980.

A Proud Moment for my Dad, no doubt.

List of Honorary Lignite Louie's in 1980

Phillip George Gent, Gordon Conrad, Herbert Dronsfield, William Chodak,

Michael Gieb, Irven Soren Christenson, Werner Conrad Rheindel,

Selmer Fonstad, Samuel Dzuba, Marcus Adam Asbenlieder,

Ralph Orie Cooley, Orin Cooley, Willard Cooley, Raymond A. Vantomme,

Howard Day, Frank Sernick, Andre M. Vantomme, Chris M. Wanner,

Steve Ostepchuk, Harry B. Budd, James M. Mann, Frank Klyne,

Edward Chamney, Clarence Crumly

Links below are not my sites, and may or

may not work Interested in the geology of the area?

http://earthnet-geonet.ca/vft/sask/rwe/stop6_e.php

Resource map of

Sask.

http://www.ir.gov.sk.ca/resourcemap

Encyclopaedia of SK

http://esask.uregina.ca/entry/coal.html

|